Cylinder Station HP 250 Frontline

Chroma Gas Sdn BhdType: Sale

2x1 cylinder (bundle) single stage with automatic changeover

Description

DESCRIPTION

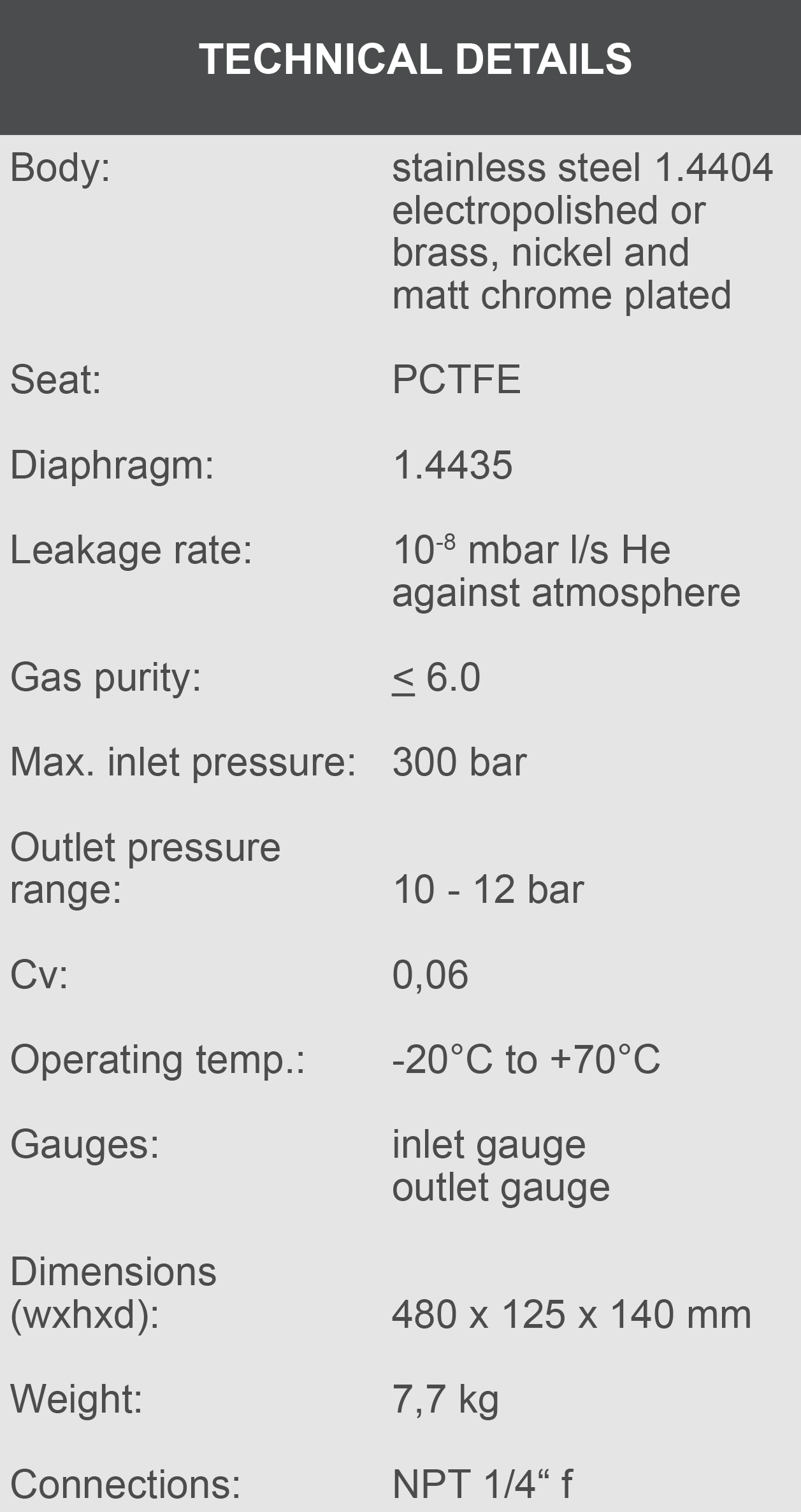

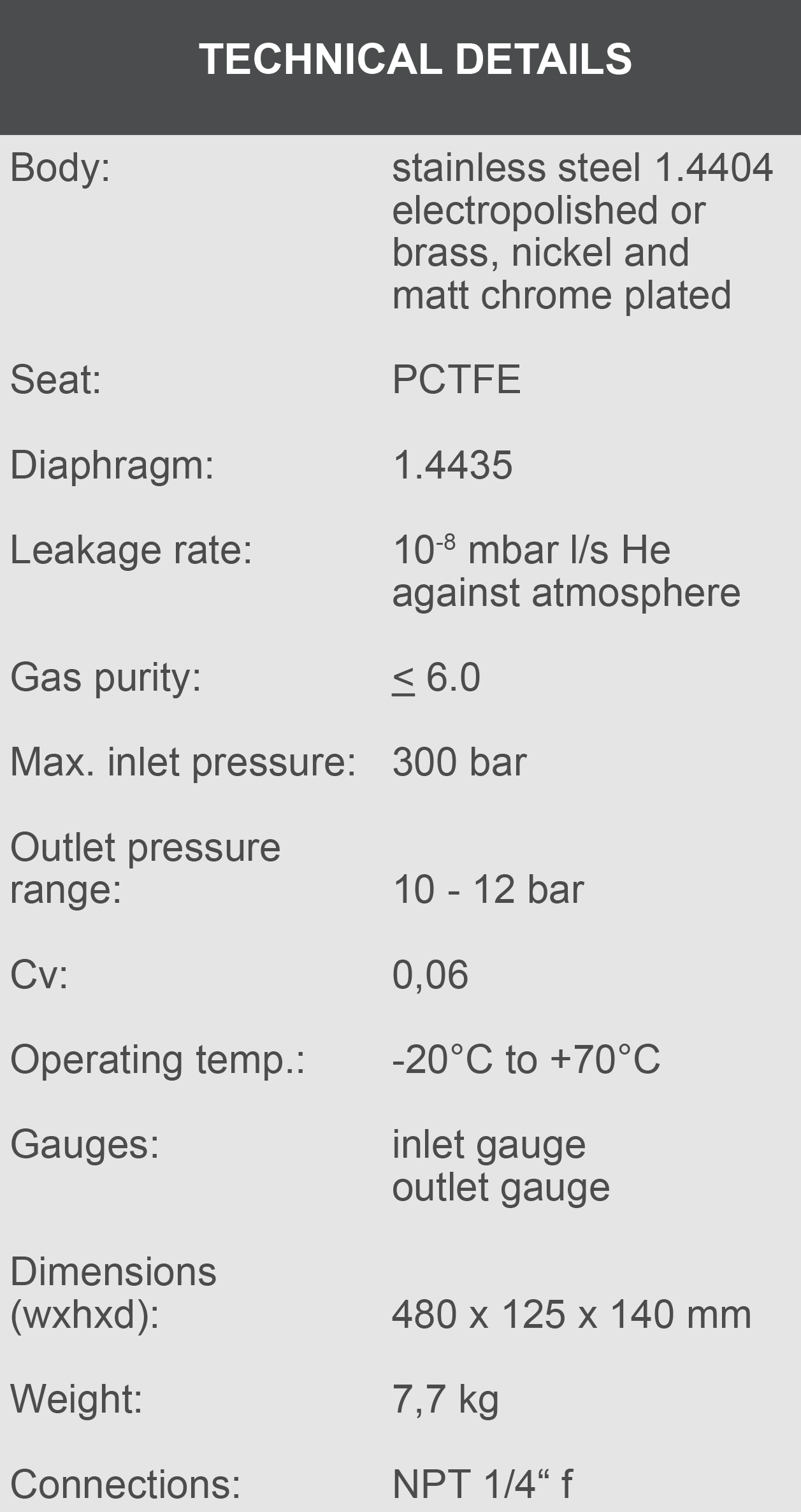

The HP 250 is a single stage panel for central gas supply with automatic changeover and internal purging. It serves the safe supply of pure and mixed gases from 2 single or 2 bundled cylinders.

The changeover takes place as soon as the pressure in the first side sinks below a predetermined level. This is controlled by two installed regulators with connected outlets.

The station is mounted on a stainless steel console consisting of a pressure regulator with in and outlet pressure gauges as well as a relief valve and shut-off valve for the process gas and purge gas.

Special characteristics:

Modular design of the pressure regulator and multifunction block. Assembly and disassembly of all fixtures from the front.

Diaphragm shut-off valve in block design for Process and purge gas with open and close display. Expandability for 1x2 or 2x2 cylinder/ bundle is already integrated. Options for external gas purging can be retrofitted without any problem.

APPLICATION AREA

Especially for gases with high requirements on purity to 6.0. secure and leak-proof where an uninterrupted supply over night and at weekends must be guaranteed.

Through options such as contact gauges and gas alarm boxes (see segment 7) is the supply concept optimised.

Through our special cleaning system our pressure regulators are suitable for ECD – applications.

QUALITY STANDARD

The company Hornung is certified to DIN EN ISO 9001 and ISO 14001:2009. All single parts are manufactured, assembled and tested by

in-house production. The finished parts are therefore under all criteria of German quality control with 100% final inspection.

The HP 250 is a single stage panel for central gas supply with automatic changeover and internal purging. It serves the safe supply of pure and mixed gases from 2 single or 2 bundled cylinders.

The changeover takes place as soon as the pressure in the first side sinks below a predetermined level. This is controlled by two installed regulators with connected outlets.

The station is mounted on a stainless steel console consisting of a pressure regulator with in and outlet pressure gauges as well as a relief valve and shut-off valve for the process gas and purge gas.

Special characteristics:

Modular design of the pressure regulator and multifunction block. Assembly and disassembly of all fixtures from the front.

Diaphragm shut-off valve in block design for Process and purge gas with open and close display. Expandability for 1x2 or 2x2 cylinder/ bundle is already integrated. Options for external gas purging can be retrofitted without any problem.

APPLICATION AREA

Especially for gases with high requirements on purity to 6.0. secure and leak-proof where an uninterrupted supply over night and at weekends must be guaranteed.

Through options such as contact gauges and gas alarm boxes (see segment 7) is the supply concept optimised.

Through our special cleaning system our pressure regulators are suitable for ECD – applications.

QUALITY STANDARD

The company Hornung is certified to DIN EN ISO 9001 and ISO 14001:2009. All single parts are manufactured, assembled and tested by

in-house production. The finished parts are therefore under all criteria of German quality control with 100% final inspection.

Company Information

| Name | : | Chroma Gas Sdn Bhd (405660-D) |

|---|---|---|

| Business Type | : | Gas - Industrial |

| Main Product | : | Gases, Gas Equipment, Cut & Weld Products, Personal Protection, Fire Fighting, Workshop Equipment, Equipment Rental, Safety Training |

| Year Established | : | |

| Location | : | Nilai |

| Website | : | https://chromagas.com/ |