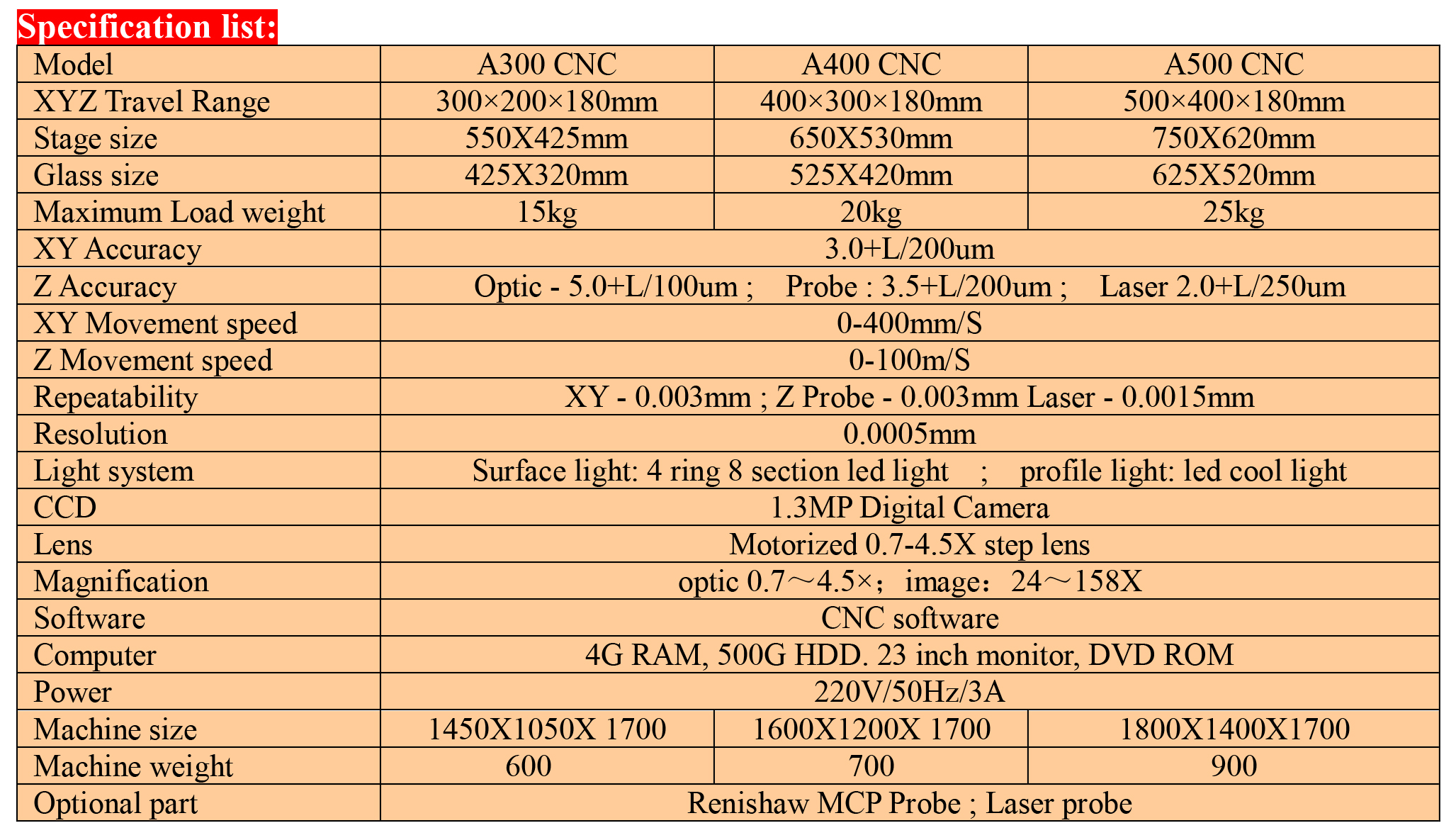

CNC Fully Automatic Video Measuring Machine

AccuLinks Systems (M) Sdn BhdType: Sale

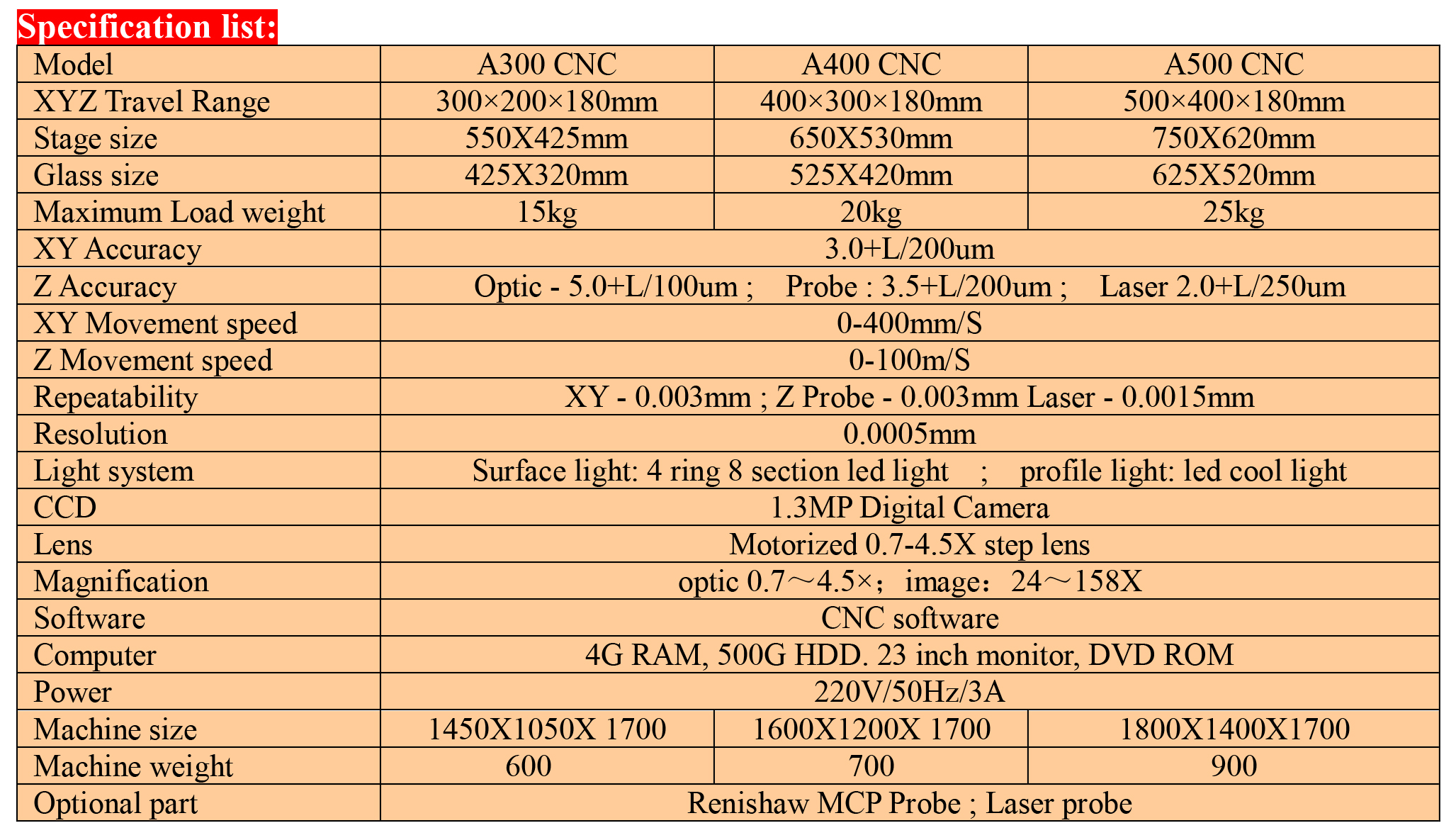

- Fully Automatic Video Measuring Machine

- 1.3MP Digital Camera

- XY travel : 200x100mm, 300x200mm, 400x300mm

- Z-axis travel : 180mm

- Accuracy : (3 + L/200)um

- 0.7 to 4.5X Zoom lens

- Total Magnification : 24X to 158X

- Auto Focus

- Auto Edge detection

- SBK4000 Fully automatic closed loop control

- Optional : Renishaw touch Probe

- Optional : Keyence/Omron Laser Sensor for Non Contact Precise Z measurement

Description

CNC Fully Automatic Video Measuring Machine is widely and suitably used in measurement services at various levels or workshops’ inspection stations in various industries of electronics, instruments and meters, cutting-tools and gripping devices, precision machine elements, precision hardware pieces, electronic components, plastic and rubber finished products, semiconductor components, punching pieces, socket connectors, die equipment, automobiles, machining operation, military industry, aerospace, etc. and colleges and universities, scientific research institutes, etc.

Feature:

◆ Precision transmission equipment design, to achieve rapid movement.

◆ The column and the base with granite structure, high precision and reliable stability.

◆ It is equipped with multifunction measurement software, to meet the different measurement requirements.

◆ Can import the DXF file for rapid measuring.

◆ The measurement data can be imported into Word, Excel, Auto CAD.

◆ Report output function, the output test results easily illustrated.

◆ High precision linear slide rail and high precision ball screw ensure the machine precision and working life.

◆ The high definition lens and high resolution CCD, be sure high definition measurement products.

◆ The advanced navigation positioning lens, easy programming and measurement procedures.

◆ Option for Renishaw probe (model AP - CNC), or install with precision laser probe to realize 3D measurement.

Optional Part:

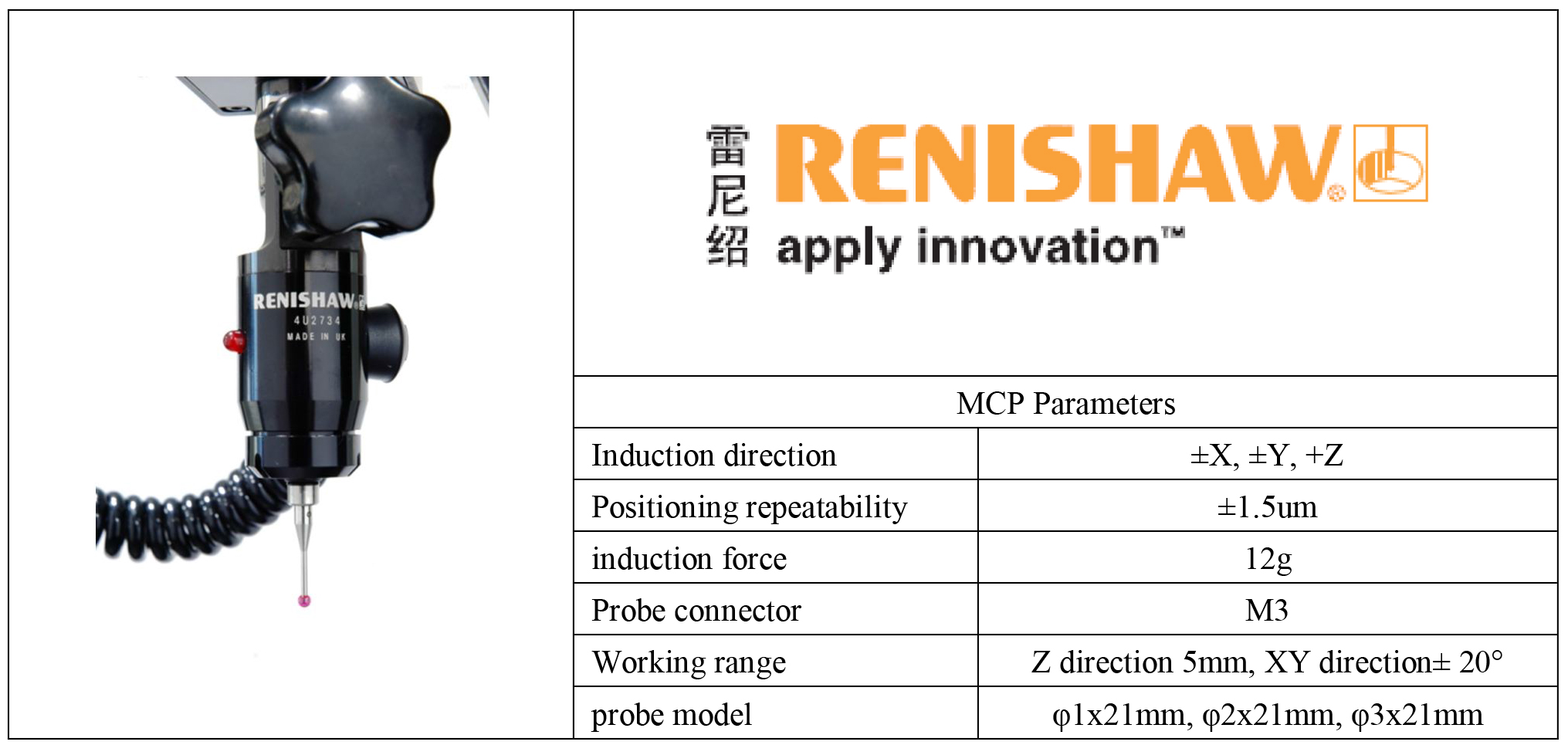

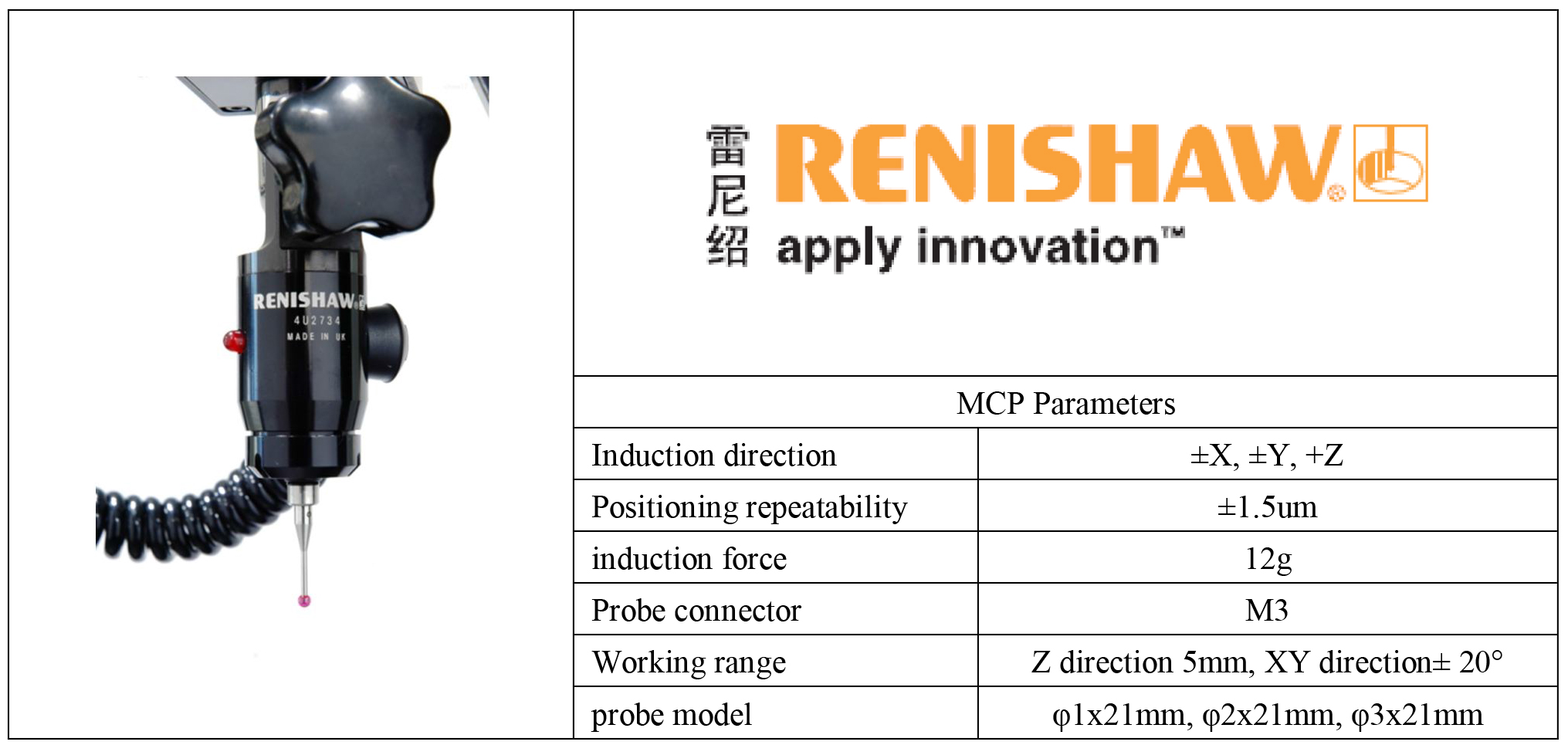

1. Renishaw MCP probe

It’s mainly used for the measurement such as: Spatial height, spatial flatness, cylinder, cone, spherical point, spatial surface, it’s contact measurement.

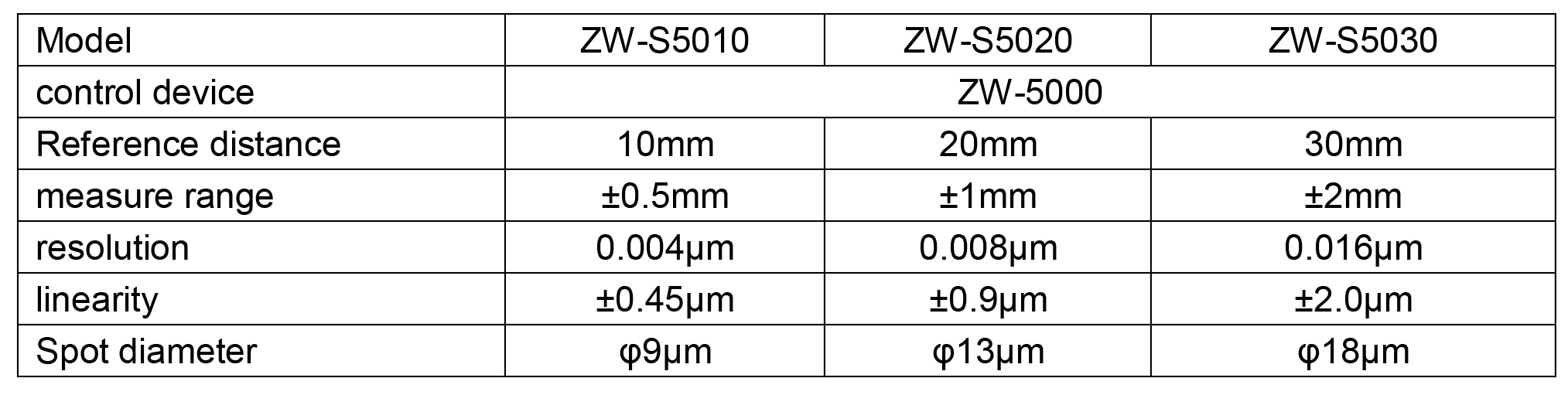

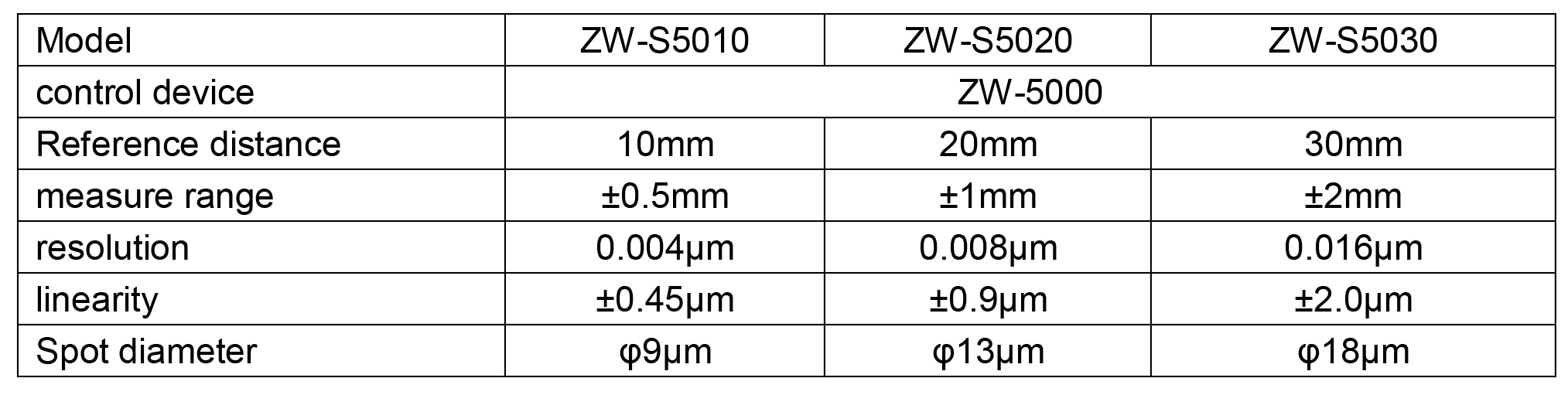

2. Omron laser sensor

It’s commonly used for the measurement such as Mobile panel, LCD backlight module, as well as automotive and mold parts for high-precision measurement requirements, it’s non-contact measurement.

Software (SBK-CNC Full Automatic measuring software)

Feature:

◆ Precision transmission equipment design, to achieve rapid movement.

◆ The column and the base with granite structure, high precision and reliable stability.

◆ It is equipped with multifunction measurement software, to meet the different measurement requirements.

◆ Can import the DXF file for rapid measuring.

◆ The measurement data can be imported into Word, Excel, Auto CAD.

◆ Report output function, the output test results easily illustrated.

◆ High precision linear slide rail and high precision ball screw ensure the machine precision and working life.

◆ The high definition lens and high resolution CCD, be sure high definition measurement products.

◆ The advanced navigation positioning lens, easy programming and measurement procedures.

◆ Option for Renishaw probe (model AP - CNC), or install with precision laser probe to realize 3D measurement.

Optional Part:

1. Renishaw MCP probe

It’s mainly used for the measurement such as: Spatial height, spatial flatness, cylinder, cone, spherical point, spatial surface, it’s contact measurement.

2. Omron laser sensor

It’s commonly used for the measurement such as Mobile panel, LCD backlight module, as well as automotive and mold parts for high-precision measurement requirements, it’s non-contact measurement.

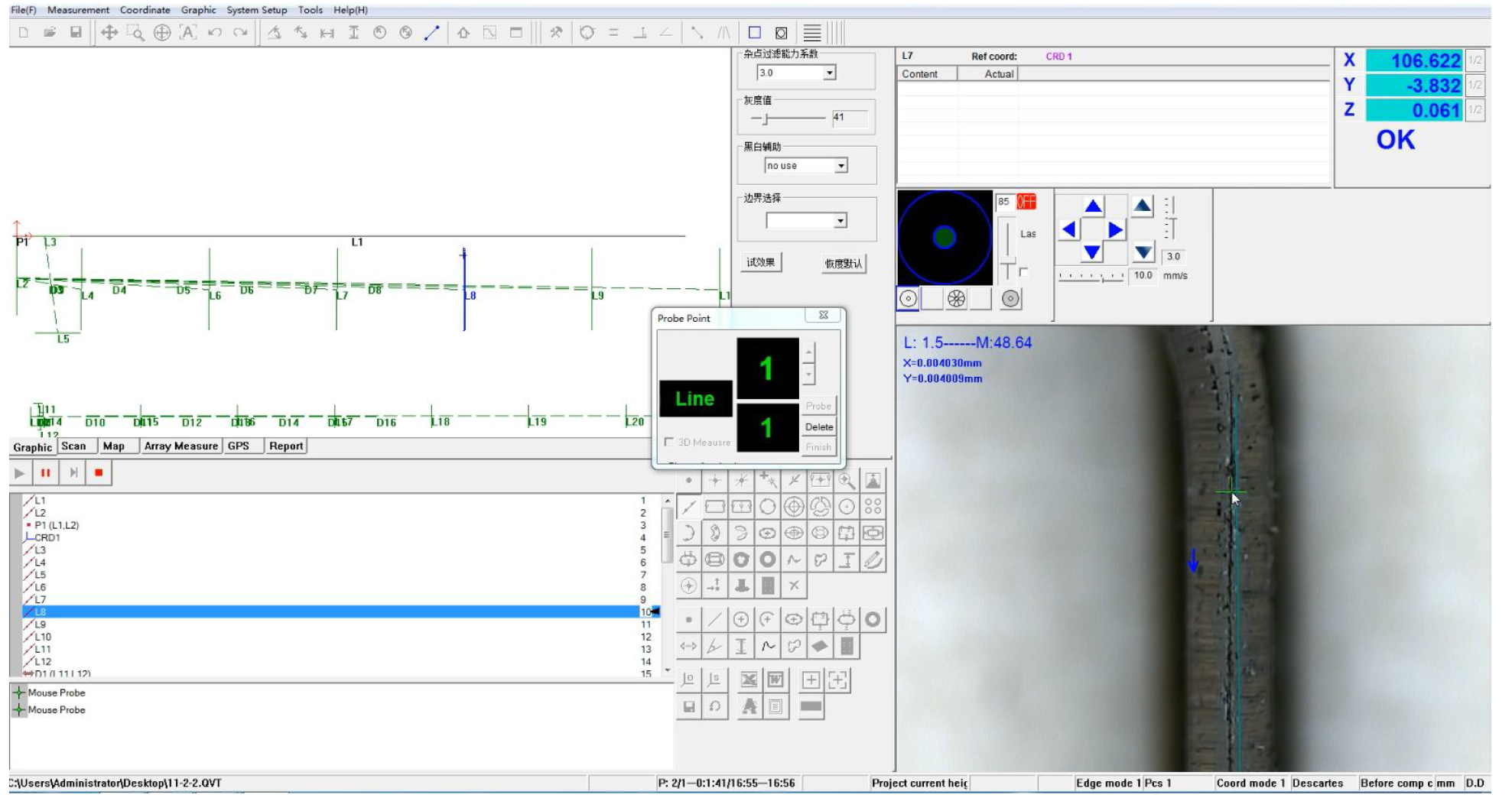

Software (SBK-CNC Full Automatic measuring software)

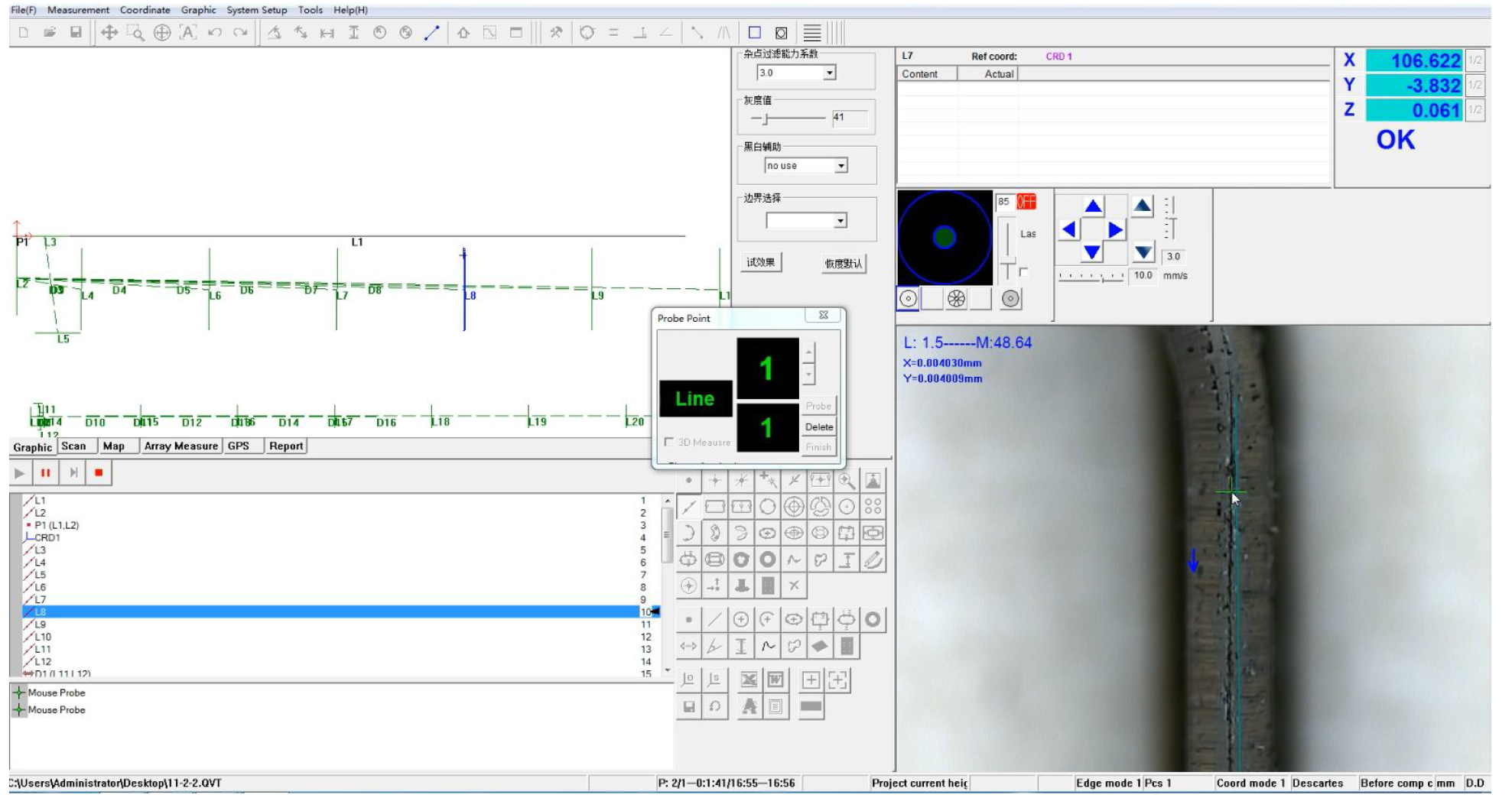

- Element measurement, It can measure 12 elements (point, line, circle, arc, ellipse, rectangle, groove, ring, distance, angle, open cloud line, closed cloud line)

- Macro measurement function, to associate some of the measurement construction commands to a button, reduce the number of users to operate the mouse, improve work efficiency.

- Automatic capture measurement, using the mouse circle to hold the edge of the workpiece, the line, circle, or arc can be obtained automatically

- Element structure, The construction of elements provides 10 construction methods: translation, rotation, extraction, combination, parallelism, image recognition, symmetry, intersection.

- Rich display results, The measurement results of various elements show that the amount of information is large enough to meet the needs of various customers

- Can display optical magnification and screen magnification,

- Coordinate system, the multiple coordinate system can be set up according to the drawing, and the coordinate transformation of each coordinate system can be realized.

- User program, Unrestricted user program recording, editing, saving, and exhaling function, The user program can record and edit all the user actions to achieve the replication measurement and greatly improve the measurement efficiency.

- Auxiliary dimming, The dimming indicator will indicate to the user what time the best light intensity, measuring error caused by light is avoided

- Graphic function, With perfect graphics processing and display function (zoom, translation, window display, partial enlargement and full screen display)

- Annotation function, It can directly mark the angle, distance, X direction distance, Y direction distance, circle (ARC) radius, circle (ARC) diameter and arc length in the drawing area and image area element graphics

- System error correction, The software has a system error correction function.

- Scan function

- Large MAP function, The workpiece can be divided into many areas to take pictures, form a large map, and can be tagged on the map.

- Language conversion, Support all languages

- Report function, The measurement data can be exported to Excel, Word, AutoCAD and TXT.

Company Information

| Name | : | AccuLinks Systems (M) Sdn Bhd (742506-V) |

|---|---|---|

| Business Type | : | Measuring Equipment & Supplies |

| Main Product | : | optical microscope, profile projector, VMM, CMM, Portable CMM, video CMM, salt spray, tensile tester, hardness tester, XRF Elemental Analyzer, Oven, Temperature and Humidity Test Chamber, etc. |

| Year Established | : | 2006 |

| Location | : | Shah Alam, Penang, Malacca |

| Website | : | http://www.acculinks.com |